UV glue curing does not necessarily require the use of LED UV curing lamps; here are some common light sources that can be used for curing UV glue:

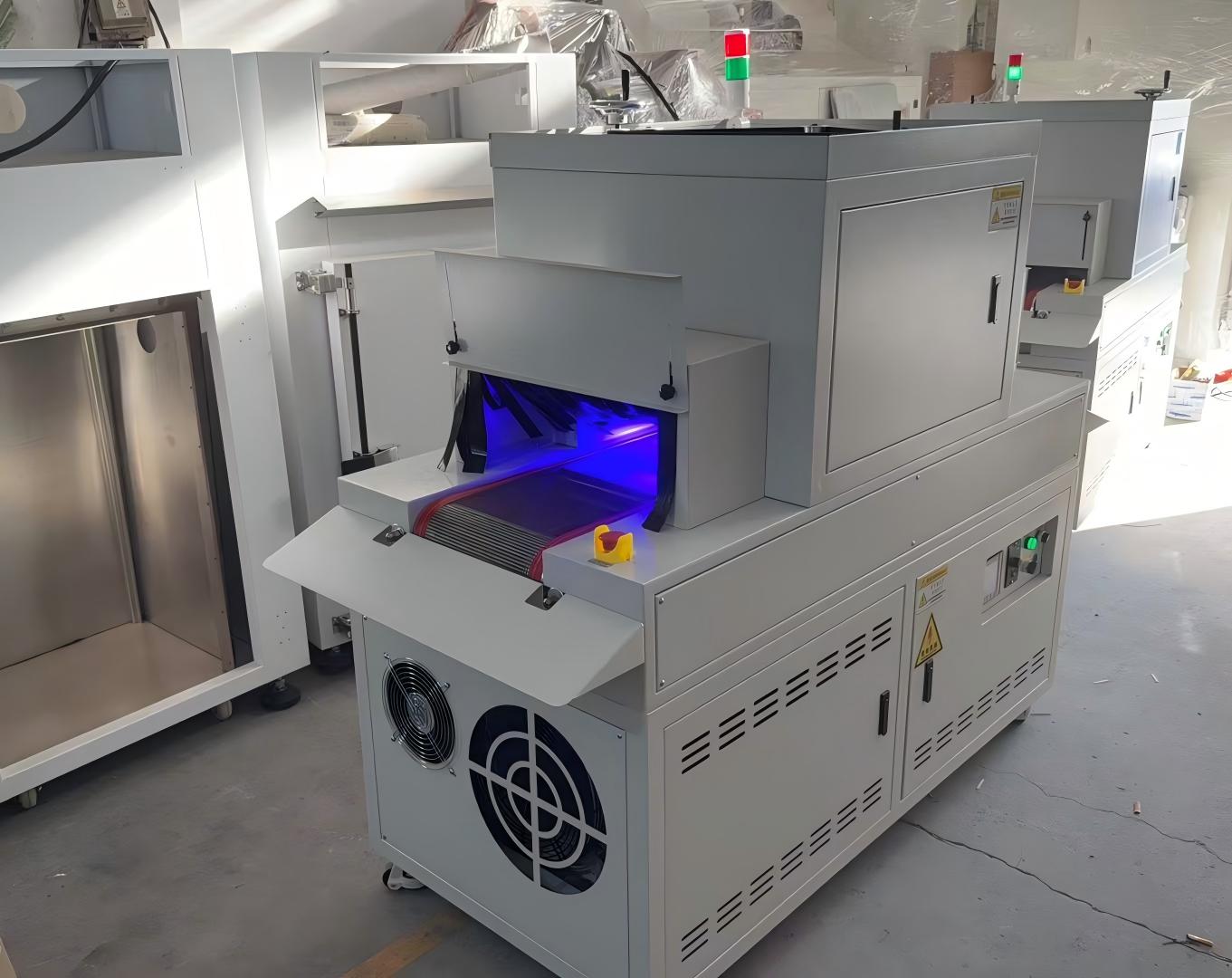

LED UV curing lamp

- principle:LED UV curing lamps emit ultraviolet light of specific wavelengths, causing the photoinitiators in UV adhesives to absorb energy and generate active free radicals or cations. This process triggers polymerization and cross-linking reactions, enabling the adhesive to transition from a liquid to a solid state in a short period of time.

- advantages:LED UV curing lamps feature cold light sources and no thermal radiation, making them particularly suitable for materials that are sensitive to temperature. They prevent issues such as material deformation caused by overheating. With their narrow wavelength and high concentration of light energy, these lamps enable more precise curing, resulting in better uniformity of the curing process. They also have a long service life and low maintenance costs. In addition, they are environmentally friendly and safe to use.

- application:It is widely used in numerous fields such as electronics, optics, medicine, and crafts, including the bonding of components for mobile phones and computers, the gluing of optical lenses, the assembly of medical devices, and the production of jewelry.

mercury lamp

- principle:When a mercury lamp is powered on, the mercury atoms are excited, emitting ultraviolet light, which in turn triggers the curing reaction of UV adhesive.

- advantages:Mercury lamps have higher power and produce stronger light intensity, which means they may cure materials more quickly than LED UV curing lamps. This is especially true for applications involving large areas or thick adhesive layers that require rapid curing, as the process can be completed in a much shorter time.

- disadvantages:Mercury lamps have several significant disadvantages. For instance, they are expensive to purchase and maintain. The spectrum they emit is wide, and only a portion of the energy is in the ultraviolet range that is effective for curing materials. A large amount of visible light and infrared radiation is also produced, generating significant heat that can cause the workpieces being processed to deform. These lamps are not suitable for materials that are sensitive to heat and can also cause serious damage to the eyes of those operating them. In addition, mercury lamps pose a risk of mercury pollution.

- application:Despite its many shortcomings, it still finds certain applications in industrial production scenarios where there are extremely high requirements for curing speed, while the demands for temperature control and environmental protection are relatively lower..

sunlight

- principle:Sunlight contains ultraviolet rays. When UV glue is exposed to sunlight, the photoinitiator in it absorbs the energy of these ultraviolet rays, thereby triggering the curing process..

- advantages:As a natural source of light, sunlight requires no additional equipment and has low costs. It is also an inexhaustible resource..

- disadvantages:The intensity of ultraviolet rays in sunlight is greatly influenced by factors such as weather, time, and geographical location. It is unstable and difficult to control, making it impossible to accurately predict the curing time. Therefore, this method is only suitable for applications where the requirements for curing effects are not high, and there is sufficient time to wait for the curing process to complete. Examples include some temporary repairs outdoors or simple bonding tasks.

- application:It is generally suitable for UV adhesive applications in outdoor environments that require small areas and low levels of strength, such as minor repairs or temporary fixation of outdoor billboards.。

Other ultraviolet light sources

- UV fluorescent lamp:Ultraviolet fluorescent lamps can also emit ultraviolet light, which helps to cure UV adhesives. Their advantages include relatively low cost and ease of use; however, their lower power results in a slower curing speed. Therefore, they are suitable for small-scale UV adhesive applications where fast curing is not a critical requirement, such as home handicrafts or the bonding of small models.

- ultraviolet laser:Ultraviolet lasers possess characteristics such as high energy density, high monochromaticity, and good directionality, enabling high-precision and rapid curing of UV adhesives. They are particularly suitable for micro-nano processing applications that require extremely high curing accuracy and speed, such as microelectronic packaging and optical component manufacturing. However, ultraviolet laser equipment is expensive, has high operating costs, and also demands high technical expertise from operators.。